Products

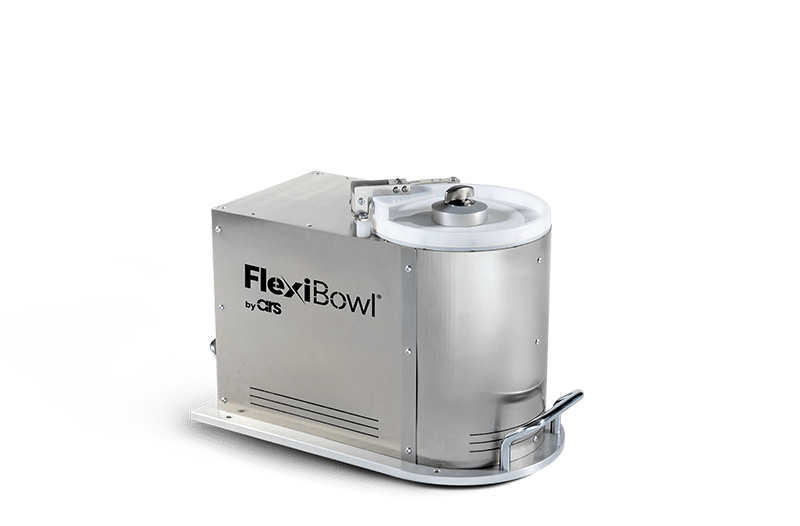

FlexiBowl® 200

ideal for 1-10 mm parts

- Recommended part size 1-10 mm

- Recommended part weight <20 g

- Backlight area 90 cm²

- Backlight area (dimensions) 180 x 90.5 mm

- Payload 1 kg

- Recommended capacity of the linear pre-feeder 1.5 l

- Floor plan footprint 254 x 470 mm

- Height of removal surface 270 mm

FlexiBowl® 350

ideal for 1-20 mm parts

- Recommended part size 1-20 mm

- Recommended part weight <40 g

- Backlight area 166 cm²

- Backlight area (dimensions) 111 x 230 mm

- Payload 3 kg

- Recommended capacity of the linear pre-feeder 5/10 l

- Floor plan footprint 447 mm

- Height of removal surface 270 mm

FlexiBowl® 500

ideal for 5-50 mm parts

- Recommended part size 5-50 mm

- Recommended part weight <100 g

- Backlight area 513 cm²

- Backlight area (dimensions) 334 x 167 mm

- Payload 7 kg

- Recommended capacity of the linear pre-feeder 10/20 l

- Floor plan footprint 629 mm

- Height of removal surface 270 mm

FlexiBowl® 500 E

rotary disc with increased edge

- Recommended part size 5-50 mm

- Recommended part weight <100 g

- Backlight area 513 cm²

- Backlight area (dimensions) 334 x 167 mm

- Payload 7 kg

- Recommended capacity of the linear pre-feeder 10/20 l

- Floor plan footprint 629 mm

- Height of removal surface 270 mm

FlexiBowl® 650

ideal for 20-110 mm parts

- Recommended part size 1-20-110 mm

- Recommended part weight <170 g

- Backlight area 922 cm²

- Backlight area (dimensions) 404 x 250 mm

- Payload 7 kg

- Recommended capacity of the linear pre-feeder 20/40 l

- Floor plan footprint 788 mm

- Height of removal surface 270 mm

FlexiBowl® 800

ideal for 60-250 mm parts

- Recommended part size 60-250 mm

- Recommended part weight <250 g

- Backlight area 1125 cm²

- Backlight area (dimensions) 404 x 325 mm

- Payload 7 kg

- Recommended capacity of the linear pre-feeder 20/40 l

- Floor plan footprint 941 mm

- Height of removal surface 270 mm

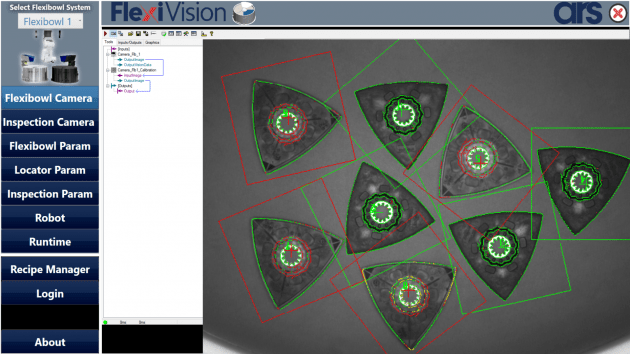

FlexiVision

FlexiVision is the PC Vision Software for robot guidance that is optionally available with FlexiBowl® systems. It is developed with Cognex VisionPro library tools, supports multiple cameras and offers great flexibility. The system is compatible with many industrial robots and enables the rapid development of FlexiBowl® applications without the need for advanced programming skills.

The main functions of the system include:

- Dynamic control of all FlexiBowl® system parameters (acceleration, speed, angle, ...)

- Control of the pre-feeder using a histogram

- Calibration of robot and camera system

- Models of parts using machine vision

- Coordinates for the robot

- Robotic Pick&Place operations

- Robot communication control

- Program management

- Comparison of pattern and geometry

Large-volume pre-feeders

Large-volume pre-feeders are used to stock bulk materials and are particularly suitable for filling and continuous dosage of small and medium-sized parts in a wide range of applications. They are driven by a linear vibration base and are perfectly aligned with the FlexiBowl® system. Large-volume pre-feeders are available in different volumes: 1.5 lt, 5lt, 10lt, 20lt, 40lt, according to the requirement for parts handling related to system productivity.

They are standardly made of INOX steel, they can be coated with polyurethane upon request. There are a number of useful accessories such as front and rear flap, hand protector, 110V / 230V power supply, etc.

Standard design

Standard design Polyurethane design

Polyurethane designOur customers

We cooperate

Copyright © 2025 VSP Technology